CNC: CNC skills – the industry-education gap

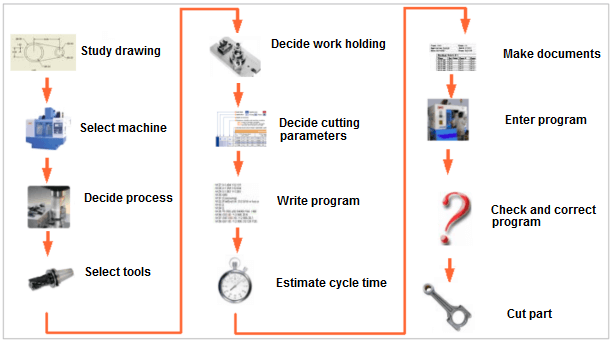

The picture below shows the steps involved in machining a part on a CNC lathe or machining center. There are 12 steps, and each step is a skill to be imparted.

However, the typical syllabus in India at the Diploma and BE levels only has programming, just 1 of the 12 skills. When we talk of the industry-institute gap, in this case it is a horrendous 92 % (11 out of 12 skills missing). There’s this general misconception that you just write a CNC program and feed it into the machine, and the machine then runs itself.

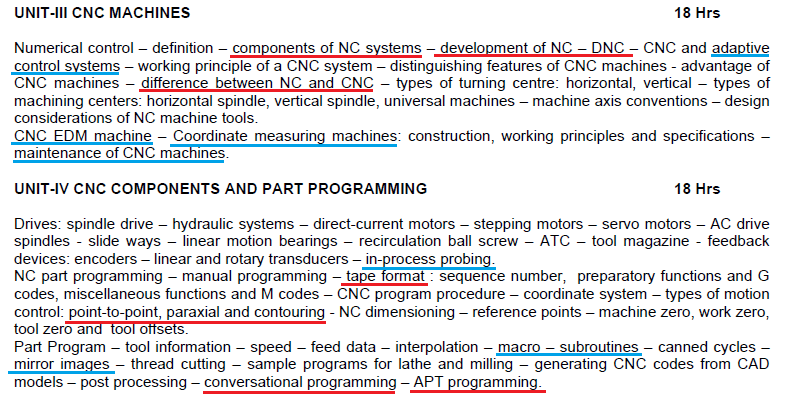

Here’s an example of the syllabus of Diploma in Mechanical Engineering, in a reputed private university. This is typical of a lot of syllabi, characterized by obsolete or unnecessary topics. Also characterizied by inclusion of advanced topics that have no place in basic learning – like teaching the XYZs when you’ve not even taught the ABCs. Topics underlined in red are obsolete and unnecessary. Those marked in blue are too advanced, better learnt in industry on the job. You’ll notice that only some basic machine construction and programming are covered, and there’s nothing else other than these.

of topics that need to be covered in CNC machining. If you have enough time to cover all these topics (like in an elective), you can include all of them. Alternatively, you can replace some of the current topics in your syllabus with topics from this list.

For some years now I have been part of the syllabus committee in some universities. I’m available in case you want me as part of the syllabus committee or even just for a quick consult. All for free

Etc.

IMTEX 2017

IMTEX 2017, India’s biggest manufacturing technology show, was in the last week of January. It was a great show this year, far bigger than 2015. For Cadem it was particularly good because we won the prestigious FIE Foundation innovation award.

The FIE Foundation award is given every IMTEX (that’s once in 2 years) to a handful of products to recognize Innovations and Product Vision in Machine Tool technology. Cadem won the award this time for Leanworxcloud, a cloud-based production and productivity tracking system for SMEs.

The system has a tracking device connected to a machine that collects data, and makes reports available on the internet for production, OEE, maintenance, rejections, etc. You also get alerts on your mobile phone in case of abnormal production, machine breakdown.

Machine monitoring systems typically require big investment and long time for installation, putting them out of reach of SMEs. Leanworxs Cloud on the contrary is extremely affordable, and can be installed in a couple of hours, bringing IOT and Industry 4.0 within reach of SMEs.

For the gang at Cadem, the award was all the more sweet because it came with a cheque for Rs. 1 Lakh. We’re still tackling the enquiries post the show, and haven’t got around to thinking about what to do with the money. Actually, the what is a foregone conclusion, something that will involve gastronomy in a big way. Only the where is to be decided.