CNC: Anvils in threading tools – small things that make a big difference

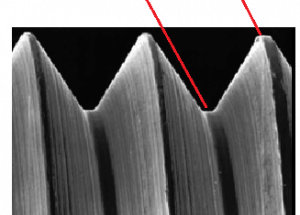

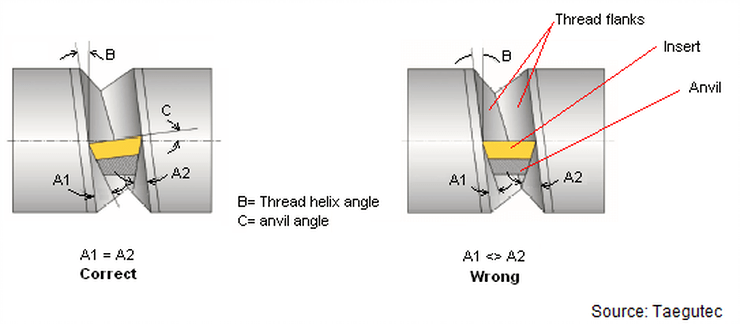

The insert is therefore seated at a sideways angle on an Anvil, or Shim – some manufacurers call it an anvil, and some call it a shim. The anvil orients the cutting edge so that it is perpendicular to the flank, and the clearance angle on both sides is equal. An appropriate anvil must be used based on the helix angle of the thread.

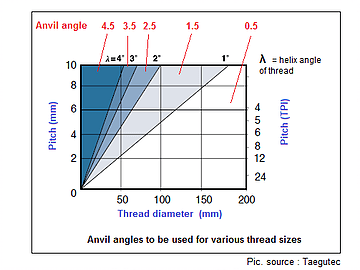

The picture shows the helix angle for various combinations of thread diameter and pitch. E.g., if the thread diameter is 50 mm and pitch is 4 mm, the helix angle is somewhere between 1 and 2 degrees, closer to 2. Cutting tool manufacturers have standard anvils from 0.5 and 4.5 degrees, in steps of 1 degree. Each coloured band in the picture represents an anvil angle. E.g., if your thread size falls in the white band, use an anvil of 0.5 degree.

Action point

When you buy a threading holder, it comes with an anvil of 1.5 degrees. Use the graph in the picture above to quickly determine the anvil angle, and use the appropriate anvil.

Etc.

A memorable customer visit

One of my memorable customer visits was to a CNC job shop in a small village in Manesar, on the outskirts of the National Capital Region (NCR). After a very tasty and colourful Haryanvi lunch (dal, sabzi, raitha, salad and fried green chillies) I walked over to a carpenter’s shop next door, and was invited by the owner to smoke a hookah with him. In keeping with the leisurely pace of a village, he had a bunch of friends hanging around chatting and seemed to be spending more time at the hookah than on his work – my dream life.

View from customer’s works

The lunch

My dream life

This must also be the only customer of ours who has peacocks roaming around the premises. I always find it delightful that these beautiful birds are so common in the NCR, roaming around like chickens. We used to have an office in Faridabad where they would be perched on the balcony wall in front through the day.