CNC threading: G76 Fanuc threading cycle – first depth of cut calculation

CNC threading often fails because of improper depths of cut. Too high depth of cut causes excessive load on the tool and part, high tool wear, and poor part quality. Too low depth of cut causes high cycle time and work hardening. In the G76 Fanuc threading cycle you have to specify the first depth of cut. This is also common to other controllers like Haas and Mitsubishi.

Calculating the first depth of cut involves a simple formula, but is not done on 90 % of shop floors. Most programmers have a thumb rule that has no scientific basis.

Here’s the explanation

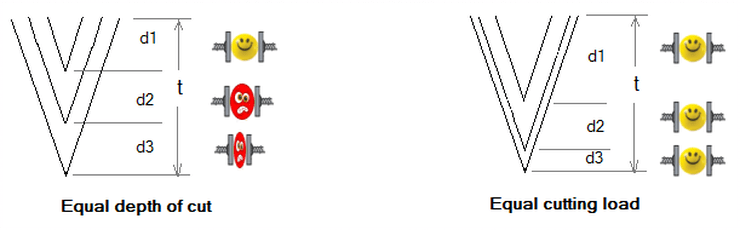

The cutting load is proportional to the cross sectional area of material being removed. If the depths of cut are constant, the load increases with each cut. The load in cut 2 is twice that in cut 1, in cut 3 it is 4 times more than in cut 1, in cut 4 it is 6 times more, etc. Disastrous for the tool and the part.

To prevent this, controllers have a constant area cutting logic in the threading cycle. The depth of each successive cut is reduced to keep the cutting area and hence cutting load constant. Unfortunately for the programmer, the G76 Fanuc threading cycle (as well as on Haas and Mitsubishi) requires that you specify the first depth of cut in the threading cycle command. They calculate the remaining depths of cut from this. This involves a small calculation, and most programmers do not do this, ending up getting the thread right after some trial and error that involves rejecting a few parts.

This is how you calculate the first depth of cut – just 3 steps:

1. Determine the number of cuts based on the workpiece material, type of thread (Metric, UNI, etc.) and the pitch, from the tool manufacturer’s catalog.

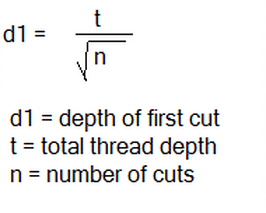

2. Use this formula to determine the first depth of cut.

E.g., if the thread depth is 1.28 and the number of cuts is 8, the depth of the first cut is 0.45.

3. Use this value in the threading cycle. E.g. on a Fanuc controller you would program this as Q450 in the second line of the G76 cycle (the value is programmed in microns in Fanuc).

Action point

Ensure that this simple method is used for calculating the first thread depth to program threading.

OR

Get a software like CADEM CAPSturn CNC lathe programming software that automatically determines the number of cuts based on the type and size of thread, and outputs the correct value in the threading cycle in the program.

Transform production and profits dramatically, in just a few months.

With a CNC machine monitoring system.

Etc

A grave matter

I was in Aurangabad recently, the city named after Aurangazeb (1618-1707). Aurangazeb was quite a monster – had two of his brothers executed, and imprisoned his father Shah Jahan in Agra Fort till his death. After executing his eldest brother Dara Shikoh, he actually took Dara’s head to show his father (“Dad, Dara wanted to meet you one final time, so I got him to see you, heh, heh.”). The Taj Mahal is his mother Mumtaz Mahal’s tomb. His great-grandfather was Akbar.

I saw Aurangazeb’s tomb in Khuldabad, near Aurangabad. A remarkably simple structure compared to his wife’s and mother’s tombs. In the final years of his life, he is said to have knitted caps and sold them anonymously in the market, out of which he made around Rs. 14. He specified that his grave must be simple, funded solely from this money. Quite a contrast to his younger years spent bumping off various friends and relatives in his pursuit of power and wealth.

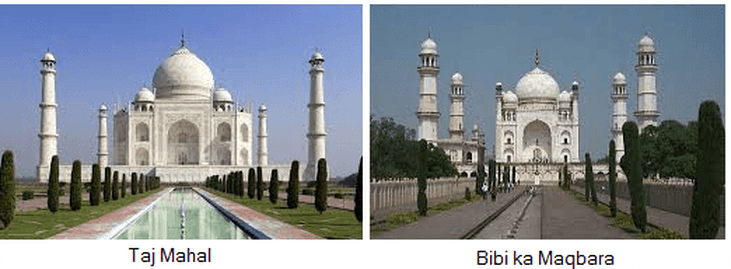

The tomb of his wife (Dilras Banu Begum), in Aurangabad, in contrast is a large monument that is a copy of the Taj Mahal. It’s called Bibi ka Maqbara, which means ‘Tomb of the Lady’ in Urdu. Its architect was the son of the architect of the Taj Mahal (small world, huh ?). The grave has a lot of notes and coins thrown in by visitors, a sign of their reverence for her.

It was initially designed to rival the Taj Mahal, but finally turned out to be an emaciated version of the original (actually looks like a Taj Mahal that went on a juice-only crash diet for 6 months – see the comparison picture). It was commissioned by Aurangazeb’s son, and the down scaling was caused by Aurangazeb cutting the budget (“Son, I think I’ve spent enough on your mom. I’ve moved on to another, hotter babe, and wooing her is costing me a bomb – restaurant bills and stuff, you know?”).