How Quick change tool holder systems improve your profits

A Quick change tool holder, or Quick change tooling, is a modular system that enables tools to be changed very fast on the machine during:

1. Initial part setup

2. Tool change due to tool wear

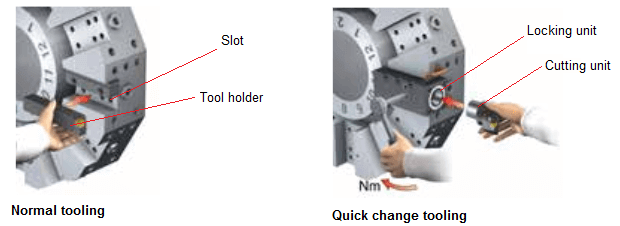

The system dramatically reduces machine downtime for tool change during setup changes, and for changing worn out inserts during machining. A normal tool is clamped by inserting it in a slot in the turret and tightening screws to hold it firmly. While doing this, care must be taken to seat the holder properly against available butting surfaces. Finally, the tool offsets must be taken by touching the part or taking skin cuts. The whole process can take 5 to 10 minutes.

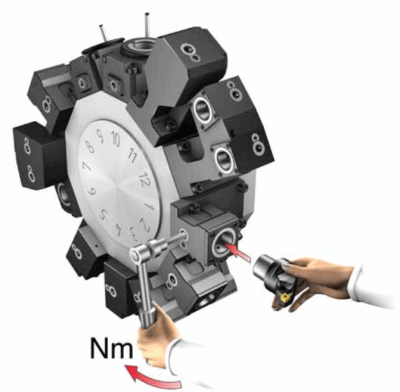

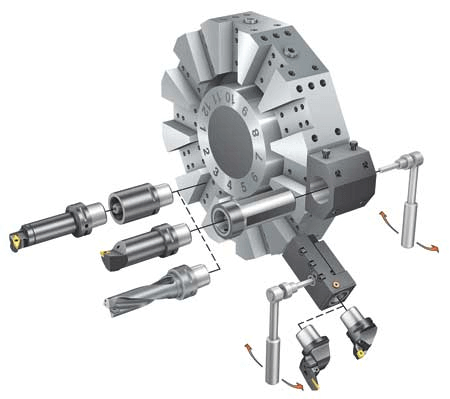

With a quick change tool holder, you do not clamp the tool directly in the turret. The tool is replaced by an interchangeable cutting unit. You insert the cutting unit into a standardized locking unit. There are different locking units for internal and external tools, and the locking units remain on the turret forever – there is no need to keep removing them for every part. The interface between the units is such that the cutting unit will only sit in a particular position in the locking unit, and will sit accurately every time. Because of the high precision of the coupling and self-centering design, repeatability can be as high as +/- 2 microns for the same cutting unit in the same female receiver. When doing the setup for a new part, you just quickly insert and clamp a new set of cutting units into the appropriate locking units. The tool offsets are pre-determined for each cutting unit, and remain the same every time that you put in the unit. Tool change time is 30 seconds, against 5 to 10 minutes for normal tooling.

Quick change tooling is more important on lathes than machining centers. This is because tool setup is anyway done offline, on pre-setters. You are not bothered so much about the time of changing tools because there is no machine down time involved in this.

Action point

If the lathes on your shop floor have frequent setup changes, think of buying quick change tooling instead of regular tools. The initial capital cost is much more than standard tool holders, but you recover the investment very fast. E.g., if the total tool change time in a setup is half an hour, you do 2 setup changes a day, and your machine costs Rs. 300 per hour, the cost of downtime is Rs. 300 per day, or Rs. 7500 per month.

Text source: Cadem NCyclopedia multimedia CNC training software.

Transform production and profits dramatically, in just a few months.

With a CNC machine monitoring system.

Etc

The Great Indian Dog Show

Periodically, in Bangalore there’s something called the Great Indian Dog Show, restricted to Indian dog breeds (alias mongrel, alias street dog, alias road nayi – in Kannada). The main point of the show is for the humans and dogs to get together, meet up and have fun.

We have two dogs, Laila and Shakuntala, both adopted off the street. We took Laila (named for her beautiful black eyes – Laila means ‘night’ in Arabic) along to the show some time ago. Our other dog, Shakuntala is scared to death of riding in a car, still believes that the Earth is flat, and that its edge is right where our home’s front gate ends. Shakuntala hates going out while Laila loves it, so we took only her to the dog show.

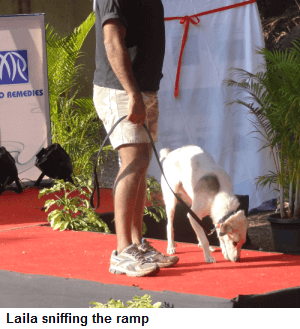

The dogs get prizes like Waggiest Tail, Serial Kisser, Showstopper and Survivor of the Year. These were judged during a ramp walk that the dog and the owner did together (there was actually a ramp and music for this). During the ramp walk, Laila refused to wag her tail madly, kiss anyone madly, or do anything that would entitle her to a prize. All she did was sniff the floor for smells of competitors who’d done the walk before her, and show her backside to the judges in the audience. Maybe she was trying for Backside of the Year, but unfortunately there was no prize for this.

‘Survivor of the year’ was won by Veeran, who’d come all the way from Chennai to participate. He’d just recovered from a series of surgeries (including amputation of a foreleg) after being run over by a car. Although Laila did not win any prize, she was in the newspapers the next day. Strangely, they said she’d won a prize for ‘Most beautiful eyes’.