Epoxy granite machine tool beds – why are they used ?

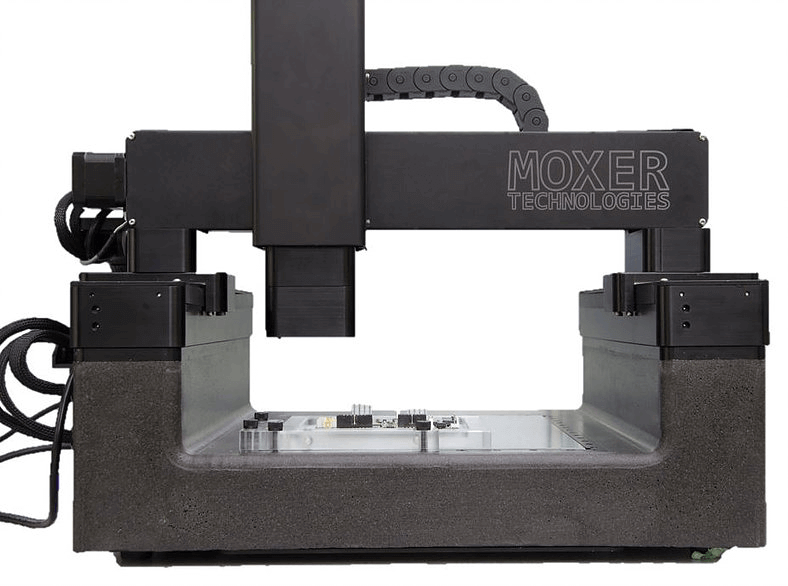

CNC machine tool beds are increasingly being made of Epoxy granite, a composite of granite aggregate and epoxy resin.

Granite aggregate is what is used in concrete in buildings. The epoxy resin is something like good old Araldite or Feviquick (can fix everything except broken hearts, according to its ad campaign), or epoxy flooring that you see on shop floors. Epoxy granite is also called epoxy concrete, for the obvious reason that it is a close cousin of the concrete that we use in building. Same granite aggregate, but epoxy instead of cement. The link above shows you how easy it is to make an epoxy granite casting.

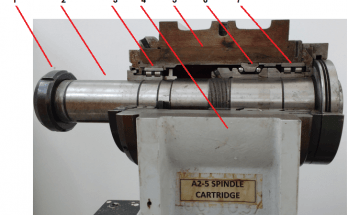

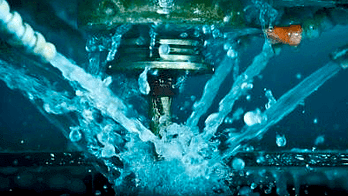

Compared to Cast Iron, epoxy granite’s vibration damping is about 10 times more, density is about 1/3, and it has higher corrosion resistance (which means it does not have to be painted). Quite a few high accuracy and high speed CNC machine tool bds are today made of epoxy granite. Making the castings too is an easier process. Since the raw materials are at room temperature, you can have accurate moulds made of other materials instead of sand moulds. The resultant casting is almost close to the final shape, requiring very little machining. The only problem is that (unlike cast iron), you cannot machine the casting. All holes and other features must be included in the casting itself. Confusingly, this stuff is known by a huge variety of names – mineral casting, polymer concrete, resin concrete, epoxy concrete, artificial granite, epoxy granite, or artificial stone.

Etc

Arak – my favourite tipple

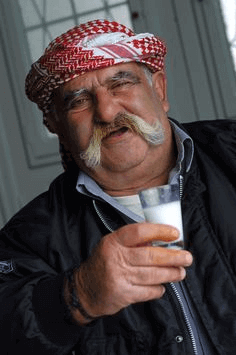

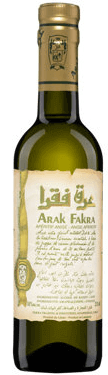

A recent business trip to Lebanon re-introduced me to Arak, and I promptly fell in love with it all over again (my first introduction to it was in Turkey a decade ago, where it is called Rakı).

Arak tastes strongly of aniseed (saunf in Hindi). It is a colourless liquid with about 60 % alcohol v/v ( strong stuff – see this earlier post for more gyan on alcohol content). It turns milky white when mixed with water. You typically mix 1/3 arak with 2/3 water.To make Arak, grapes are crushed and put in barrels to ferment, then distilled to produce alcohol. The distillate is again mixed with aniseed, and distilled a second time. Arak is mostly produced in homes on farms, in small stills.

Who’d have thought that all the distillation experiments that I did in school would finally help me understand this process ? Maybe I’d have taken more interest in the chemistry lab if my teacher had connected the experiment to this end application.

Rakı in Turkey is the same as Arak. It’s pronounced almost like Raku. The ‘ı’ is the half ‘u’ that’s also in Tamil and Japanese, pronounced like in the Tamil word irukku. The Greek Ouzo is a close cousin of Arak and Rakı, with the difference that it has added sugar and is therefore sweeter. My hotel in Beirut was very near a cozy little bar, and I would land up at the bar every evening after work, to spend the evening drinking arak and eating boiled fava beans, chatting with the barman, exchanging stories about our respective countries.

By the way, Arak is very different from Arrack that is common to India, Sri Lanka and Indonesia. The latter is made from fermented coconut flowers, sugarcane, rice or fruit. This is very strong stuff, upto 80 % alcohol v/v, almost tasteless, basically like Vodka.