What is the APT programming language ? Where is it used in CNC programming ?

APT programming language is a language for defining tool paths on CNC machines. APT is an acronym for Automatically Programmed Tool. It was the predecessor to today’s CAM software, created in the late 1950s to define complex tool paths in the aerospace industry in the US. It was developed in MIT labs, the same place where the first NC machine was invented.

APT was created before graphical user interfaces were available, and so it is based on text to specify the geometry and toolpaths needed to machine a part. It has English-like commands: GOLFT for Go Left, TANTO for Tangent to, etc.

You first write a program in APT, software converts it into a series of tool coordinates called Cutter Location Data (CLD). Another piece of software, a translator called a Postprocessor, then converts the CLD into an NC program (the G and M code program) that is understood by the machine. You feed the NC program into the machine and cut the part.

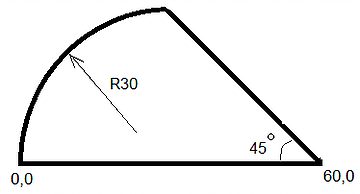

APT programming language example for milling around a part

$$ PART SHAPE DEFINITION

STRT = POINT/ -50,-20,100

P1 = POINT/0, 0, 0 P2 = POINT/60, 0, 0

P2 = POINT/30, 10, 0

L1 = LINE/P1,P2

L2 = LINE/P2,ATANGL,135

C1 = CIRCLE/CENTER, P2, RADIUS, 60

PL1 = PLANE/P1, P2, P3 PL2 = PLANE/PARLEL, PL1, ZSMALL, 5

PL3 = PLANE/PARLEL, PL1, ZLARGE, 5

$$ MOTION COMMANDS

SPINDL / 3000, CW

FEDRAT / 100, 0

COOLNT/ON

FROM /STRT

RAPID, GOTO/ L1, TO, PL3, PAST, C1

GOTO/ PL2

TLRGT, GOFWD / L1, PAST, L2

GOLFT / L2, PAST, C1

GOFWD / C1, PAST, L1

GOTO/PL3

COOLNT/OFF

GOTO / STRT

FINI

Here’s more on the APT language.

Action point

APT is obsolete, not used any more. Programming today is done manually (if the part is simple) or using CAM software with a graphical user interface. Unfortunately, a lot of educational institutions around the world still think APT is state of the art, and waste time teaching it. If you teach CNC machining somewhere and have any say at all in forming the curriculum, please remove this topic from the curriculum and replace it with something useful, like tooling, work holding, cutting parameters selection, etc.

Text and pics. source: Cadem NCyclopedia multimedia CNC training software.

Transform production and profits dramatically, in just a few months.

With a CNC machine monitoring system.

Etc

Boat anchors – getting to the bottom of the issue

Whenever I go to the sea side and see boats bobbing by the beach, I wonder how they stay there, and how a mere anchor holds them against the sea’s current, the waves and the winds.

I finally decided to educate myself at least on the ABCs of anchoring – the XYZ I’ll learn when I learn to swim (which seems very unlikely in this life) and get on boats. I found that there’s not just one type of anchor. There are a whole lot of them, each engineered to do a specific job: for snagging on rocks, tethering to sand and mud, to the sea bed that’s under the boat, etc.

The plough type holds by ploughing into the bottom sediment, and has good holding strength. The mushroom type sinks into the sediment but its holding power is weak, so it is used for small row boats and inflatable boats.

On large ships the weight of the chain and the weight of the anchor both work together to hold the ship in place. Each link in the chain can weigh 0.25 tons, and the anchor itself can weigh 100 tons. I came across this video on the web of a ship dropping its massive anchor on a tug boat by mistake. Luckily nothing seems to have happened to the pilot of the tugboat.