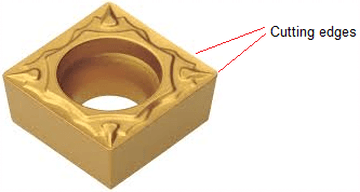

Insert selection – based on insert geometry at cutting edge and chip breaker

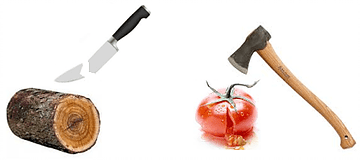

Insert selection on a lot of shop floors is often done without considering the cutting edge. Would we cut or a log of wood with a kitchen knife, or a tomato with an axe ?

No ! Because we know that this would be the result.

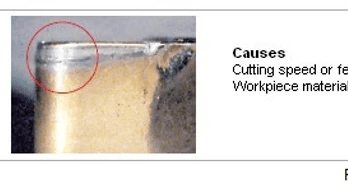

We however do the equivalent of this every day on our shop floor, when we use inserts without thinking about the cutting edge geometry. Result ? Higher cycle time, lower product quality, higher tool costs.

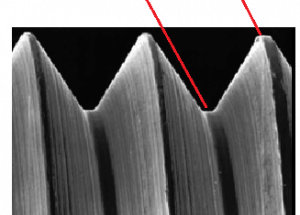

The cutting edge looks the same on all inserts, and the fancy pattern on the insert looks like it is just for aesthetics. However, these are the equivalent of the axes and the kitchen knife – they are different for different workpiece materials and applications (roughing, finishing, etc.).

Just understand the basics of insert cutting edges from this document and select the correct insert. It can dramatically reduce cycle time, improve quality, reduce tool costs, and improve profits in your CNC machining. The rules apply both to turning insert geometry and milling insert geometry.

Pic. and text source: CADEM NCyclopedia multimedia CNC training software.

Etc

Brilliant packaging, nice food

I had ‘Nungu’ (called Tari in Hindi) in Coimbatore. I’ve eaten it numerous times before, but never this way, with such nice aesthetics.

Nungu is the fruit of the Toddy palm tree, and Neera is the juice that is collected by tapping new shoots. Neera is sweet when freshly tapped, ferments and becomes the sour alcoholic drink Toddy by evening.

Here the nungu was cut into pieces, served with the Neera in the leaf of the tree. Usually the fruit and the Neera are had separately. Vast improvement over serving the Neera in boring and eco-unfriendly plastic glasses.