Fanuc G61 Exact stop check – what is it, and why is it used ?

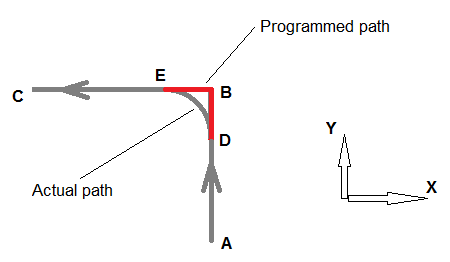

Fanuc G61 command: When you program a sharp corner in the tool path, you may not get a sharp corner. In the figure the programmed tool path is A-B-C, the line A-B followed by the line B-C. What you actually get is A-D-E-C. Because of the momentum of the machine components, axes cannot stop suddenly, and need to decelerate to a stop gradually. In this example, the X axis motion starts before the Y axis can come to a full stop. So you get a curve on the part when what you want is a sharp corner. See this explanation on CNC axes acceleration and deceleration.

See the rhino in this video making a sharp right turn at 00:20. He’s trying to turn sharp right, but actually makes a curve. He’s moving in +Y, then suddenly turns towards +X without stopping the +Y motion. Same phenomenon as the CNC machine. This by the way is an Indian rhinoceros (also called the Greater one-horned rhinoceros) running down a country road in the India state of Assam, causing panic stricken drivers to take evasive action (while cattle on the road are placidly watching the scene).

To get a sharp outside corner, you need to program an Exact stop check command. In Fanuc G61 command does this. This is a modal command, that is active till cancelled by G64. G09 is the same as G61, but is non-modal, active only for the block in which it is specified. The larger the feed rate and the size of the machine, the higher the momentum and the more the need for exact stop. Note that exact stop will increase your machining time because of the necessity of decelerating to zero. This article in CNC Cookbook has a detailed explanation and programming example on exact stop check.

Way back when I used to be a programmer on the CNC shop floor, I had a terrible experience with exact stop check on a Deckel with Dialog control. I wrote a program for milling Titanium gas turbine blades for aircraft engines, and the 3D profile tool path involved thousands of motions of 0.1 mm. I had no idea of the exact stop feature, and did not realize that the machine had exact stop ON as default when you started it. Machining took ages as result, because the axes came to a complete stop after every small 0.1 mm motion. I found out about the feature only after some months, and then set the exact stop off at the beginning of the program. I was delighted to see the drastic reduction in cycle time when I did this.

Action point

You will rarely be required to mill a sharp outside corner, and on the contrary most drawings will actually ask for sharp corners to be broken. Occasionally however, when you do require to mill a sharp corner, use the Fanuc G61 exact stop check. Or maybe use G09 instead of G61 – with the latter there is the danger of forgetting, and then you’ll be doing the whole part with exact stop unnecessarily on.

Etc

How a rumour is killing the Rhinoceros

I’ve always thought that Indian rhinos were being poached because of their use in traditional Chinese medicine, but only recently learnt that it’s a stupid rumour in Vietnam that’s the cause of the poaching.

In Vietnam, about 20 years ago there was a rumour that a prominent politician was cured of cancer through treatment with powdered rhino horn. It is also said to improve the liver and act as an aphrodisiac in Chinese medicine. Since then there has been a big increase in poaching, killing rhinos for their horns – a single horn can fetch the poachers Rs. 2 Crore. Rhinos are close to becoming an endangered species as a result, and there are only about 3500 Indian rhinos around. The Indian rhinoceros weighs 2 tons and can run at a top speed of about 50 kmph. It has almost no predators in nature, because of its size and natural body armour. The rhino’s horn is keratin, like human nails.

Big doubt: If rhino horns are the same material as our finger nails, why can’t people simply bite their fingernails and fix their health problems instead of bumping off the poor rhinos ?