CNC: Do face mill angles matter ? Square shoulder, 45 degree, what’s the big difference?

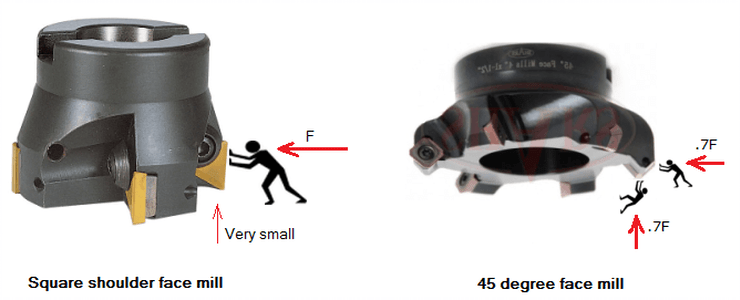

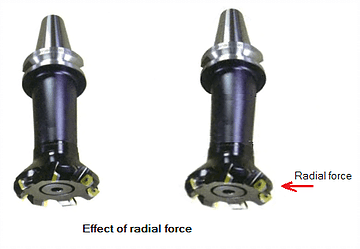

A face mill is subjected to two components of force – a radial force and an axial force. The radial force causes the arbor to bend sideways. It causes vibrations, poor surface finish, and reduces the life of the bearings in spindle.

Effect of radial force on face mill.

On a square shoulder mill the force is almost all radial, while on a 45 degree face mill is it half radial and half axial. On a 45 degree face mill, since the radial force is halved, vibration and chatter are reduced. Because of the entry angle, the shock load is reduced each time that a new insert comes in contact with the part. Surface finish improves, and so does spindle life. You can use a much higher feed rate, so machining time is reduced.

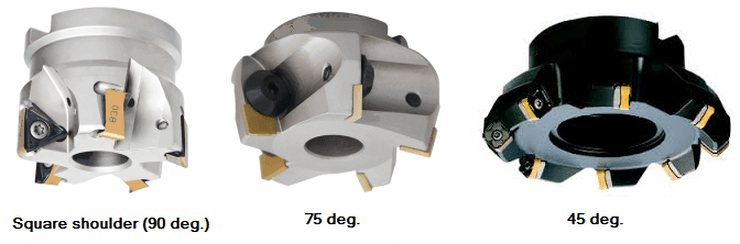

Face mill angles

The 75 degree face mill is somewhere in between the square shoulder and the 45 deg. cutter in terms of reducing radial forces and vibration. If you have to mill at a shoulder, the 75 deg. cutter allows you to go closer to the shoulder and still get some of the benefits of the angle.

Action point Use a 45 degree cutter wherever possible. Use a square shoulder face mill only when:

1. You need a square shoulder on the part.

2. The part has a weak structure or thin walls, and you need to reduce the axial force.

Etc.

Dinner at Barbecue Nation

Had dinner a while ago at a restaurant called Barbecue Nation. Its USP is that you can make your starters on your own personal grill, which is embedded in your table. You get the raw material (various meats and vegetables, paneer, mushrooms) that has been pre-marinated, and a collection of barbecue sauces. You shove whatever you want onto skewers and put them on your grill. You decide when it’s done, and dig into it.