CNC machining cost – how to reduce it by maximizing spindle power usage

You can reduce your CNC machining cost and increase profits by just improving your knowledge of something that your machine already has. And here’s the knowledge.

Is your CNC lathe a white elephant ?

An adult elephant costs Rs.3000 a day for its food and medical expenses – same as what a medium size CNC lathe costs for space, power, tooling, manpower and the occasional medicine.

Fact: Most people use their CNC machines like white elephants.

Why ? Because their programmers are obsessed about the part program, not the productivity. Because programmers think if the part is dimensionally OK, their job is done!

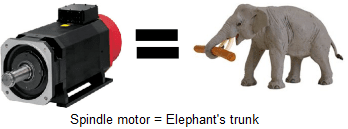

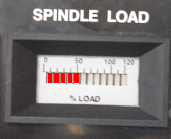

Spindle power usage in most CNC shops never exceeds 50 %. Simple logic: If you are only using 50 % of the power, your machining time is 200 % higher than what it can be. The machine spindle is like an elephant’s trunk – the part that the elephant does all its work with. If you under-utilize the machine spindle, you have a white-elephant situation !

The spindle motor on the machine is equivalent to the trunk of the elephant. Use it to the fullest extent !

Act now !

Next time you are on your shop floor, check the power meters on your CNC machines and ensure that you are using the spindle motor to its capacity in roughing operations. You can use the spindle’s continuous and half hour/10 min/15 min ratings, the power-torque curve, and the duty cycle on the part to reduce the cycle time dramatically.

Just spend 30 minutes reading this brief document that explains how to understand your machine’s spindle power specifications,

By the way, CADEM CAPSturn CNC lathe programming software does all your spindle power optimization and helps you reduce the cycle time drastically, in a few minutes. It suggests the maximum depth of cut that you can use for a selected tool, determines the available power and torque in an operation based on the diameters at which the operation is performed, and checks that these are not exceeded. It also shows you the machining time for each operation, total cycle time, cost of machining, sale price of scrap metal generated, and net machining cost. You actually do all this in 5 minutes, and increase your profits before loading the part on the machine.

It is very affordable, can cut your machining costs and increase your profits dramatically.

Etc

Kolkata trams

I think the trams are a lovely way to get around Kolkata. They are comfortable, non-polluting, energy-efficient, amazingly cheap, and add character to the city. They’re also surprisingly fast – average speed 25 kmph., max. speed 50 kmph. The average road speed in Bangalore city, by the way, is 15 kmph during peak hours.

They’ve been running since 1902. Work on 550 V DC power (what kind of a voltage is that?)

The last picture is of Vidya Balan promoting the movie ‘Dirty Picture’ on a tram.

A lot of cities like Hong Kong, Melbourne and Vienna have flourishing, widely used tram systems but in Kolkata, sadly, there’s talk of phasing them out.

http://en.wikipedia.org/wiki/Tram

http://en.wikipedia.org/wiki/Calcutta_Tramways_Company