Cutting speed vs Feed rate – difference in CNC milling

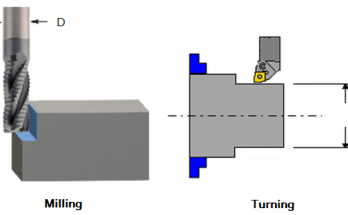

There is often confusion about cutting speed vs feed rate in milling. Here is a brief explanation. The cutting speed is the relative linear speed at which the tool moves against the part.

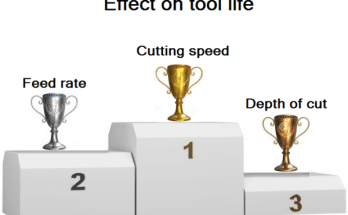

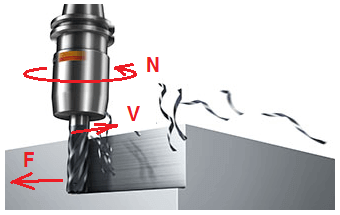

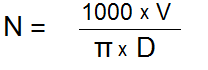

Just like we prefer to drive a car at a certain speed to get the best fuel efficiency and minimize tyre wear, in CNC milling we cut at a certain cutting speed to minimize tool wear and optimize cycle time. The tool manufacturer’s catalog recommends the cutting speed based on the tool material, workpiece material and operation. In the CNC program we however write the RPM. This equation calculates the RPM N from the cutting speed V in meters per minute (m/min)and the tool diameter D (the 1000 in the numerator meters to mm).

The Feed rate (F in the picture) is the linear speed of the tool as it travels along the part contour. A cutting tool is designed to cut a certain amount of material in each revolution, and the insert’s chip breaker geometry is designed to break chips within a particular range of chip thickness. The chip thickness directly depends on the feed rate in mm/rev. The feed rate is therefore specified in cutting tool catalogs in mm/tooth/rev (mm per tooth per revolution). It is converted to mm/min for the CNC program (note that in turning it is programmed as mm/rev).

Related posts

Cutting speed vs feed rate in CNC turning

Cutting speed formula in CNC turning, milling

Etc

Plants fighting concrete

I’ve been seeing this sight of an unusual urban forest every monsoon on my way to office. About midway to my office, I cycle down a narrow quiet street that seems to have more stray dogs than people, most of whom are my friends now (the dogs, I mean, not the people![]() ).

).

There’s an old car garage next to a house, and every monsoon a lush garden that grows on it automatically. It’s an old building, and I suppose a lot of dust has got deposited on it over the years, forming a nice thick mud layer. When it rains, seeds lying dormant in the mud must be sprouting up, resulting in a little forest. A brilliant emerald green patch, contrasting with the drab concrete around it. I see a lot of plants and trees fighting concrete, and banyans seem to be particularly adept at this.

The Banyan tree is a species of fig, and the Indian Banyan is the National tree of India. If a banyan’s seed falls on a building or wall and it happens to grow into a plant, its roots seek the ground beneath it and grow towards the ground, in the process strangling the structure below it. It’s hence also called the ‘strangler fig’.

There’s this strange story of how the Banyan got its name. The tree was common in villages and towns in India (still is), and provided a shaded place for people to hang around or for merchants to sell their goods. A lot of merchants belonged to a trading community called Bania. The tree itself got the name of the community in due course. By the way, Gandhi was a Bania, and so are many of India’s biggest business people today – Bajaj of Bajaj Auto, Lakshmi Mittal of Arcelor Mittal, the Birlas, and a whole lot of others.