Constant Cutting Speed in CNC lathes – ignorance can be expensive

Using Constant Cutting Speed (also called Constant Surface Speed or CSS) instead of constant spindle speed (constant RPM) can give you:

1. Reduced cycle time.

2. Uniform surface finish.

3. Predictable tool life

Here’s how

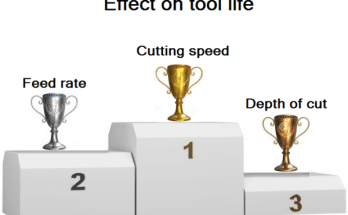

Cycle time is directly proportional to the cutting speed. A cutting tool is designed to be used at a particular cutting speed for a given workpiece material. When programming at constant RPM, programmers typically will use a lower RPM than is appropriate, resulting in lower cutting speed and than can be used. The cycle time is hence higher than it can be.

In constant cutting speed mode, with the feed rate programmed in mm/rev, the feed rate remains constant irrespective of the RPM. The surface finish is therefore uniform.

Why don’t a lot of programmers use constant cutting speed, then ?

Ignorance !

Here’s a true story. A potential customer of ours wanted a cutting trial done on his machine to see if our CAPSturn CNC lathe programming software could reduce the cycle time of a part of his, a die cast aluminium disc involving facing and boring. Our application engineer made the program in CAPSturn, ran the new program on the machine. With the new program the cycle time was less than half of the earlier one (90 secs vs. 210 earlier), the surface finish was better, and they were getting a couple of chamfers that were not proper earlier (this was because of the TNRC that CAPSturn automatically implements). We looked at the manually written program, and found that:

1. It was programmed with constant RPM, without CSS anywhere.

2. A 10 mm bore was being done with a carbide tool at 800 RPM, corresponding to 25 m/min, when it could have actually been cut at the machine’s max RPM of 4500 (which would still be lower than optimal).

When our engineer asked the firm’s programmer why he was not using the G96 command for CSS, the programmer asked “What is that?”. Simple question, that was costing the firm a lot of money.

Action point

Check if your programmer is really aware of all the concepts of programming and their benefits. If he is not, get him trained – cutting tool manufacturers and machine tool manufacturers regularly conduct training programs. Maybe occasionally get your programs vetted by an application engineer from your machine tool supplier. Even if this costs you money, it’s peanuts compared to what your programmer’s ignorance is costing you.

By the way, Cadem NCyclopedia is a great CNC training software for CNC machine operator training and CNC programming training. It has multimedia explanations on numerous topics like Constant cutting speed.

Etc

Such honesty ?

Cycling to my office in Bangalore every day, I pass by this shop where glass panes are stored outside all the time with no security even at night. I wonder how come nobody ever breaks them – the locality has such honest, ethical people ? Not once have I seen any damage caused by a night of drunken (or sober) revelry.

There’s also this other shop that has a security officer to prevent theft. He’s tied up, so that reduces his effectiveness quite a bit – unless he barks his head off and alerts the neighbours.

Some interesting facts about glass

Glass is 100 % recyclable, with no loss in quality. The energy saved by recycling one glass bottle can power a computer for 30 minutes.

All glass has these 3 basic ingredients: sand, sodium carbonate, calcium carbonate (from limestone), and some other chemicals to give the color.

Brown glass is used most often for food or drink containers, especially beer, because the amber tint reflects ultraviolet light and protects against spoilage.

One of the rare occurrences of glass in nature is when lightning strikes sand, providing enough heat to melt the sand into a long, thin type of glass called Fulgurites.