Tool life definition – it’s not when the tool breaks

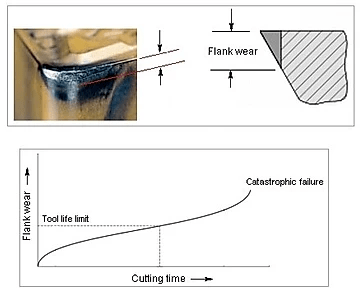

Tool life definition: Tool life is the duration of actual cutting time after which the tool is no longer usable. There are many ways of defining the tool life, and the common way of quantifying the end of a tool life is by a limit on the maximum acceptable flank wear. The term ‘acceptable’ is however subjective, and can vary from process to process. For example, the amount of wear acceptable on a rough milling insert will be more than that on a finish milling insert.

A typical tool life definition for a roughing insert would be the time period for the flank wear to become 0.5 mm. For a finishing insert it will be typically a third of this.

Tool wear is not uniform through the life of the tool. The wear is initially rapid, then settles down to a uniform rate, and finally accelerates at a very high rate till catastrophic failure occurs, which is a fracture of the tool.

Pic. and text source: CADEM NCyclopedia multimedia CNC training software.

Etc

Lunch in Gokul mess – Kanchipuram

I was driving back to Bangalore from Sriperumbur near Chennai, stopped over for lunch in the temple town of Kanchipuram, also famous for its silk sarees. I typically avoid large restaurants and ask around for the small places that serve simple local food. Some kind soul on the road directed me to the Gokul mess.

A lot of small traditional restaurants in South India are known as messes. The Gokul Mess is on a quiet road, in an old building. Nondescript outside, but very interesting inside. A barely-noticeable entrance leads into a narrow corridor that opens out into a dining area sunlit by an ingeniously designed skylight.

The beams and pillars are wooden, painted a nice shade of green.

The simple and very tasty lunch is served on a banana leaf, costs Rs. 45.