CNC – Modifying cutting speed for required tool life

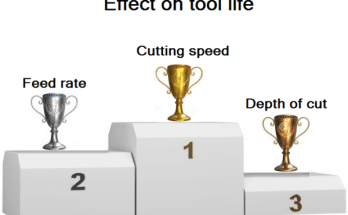

Recommended cutting speeds in tool catalogs are for a tool life of 15 minutes. This means that with these parameters the insert edge will have to be changed after 15 minutes of contact with the workpiece. E.g., if the contact time is 3 minutes in rough turning, you will have to change the rough turning edge every 5 parts. If you want a different tool life, multiply the cutting speed by the appropriate factor in this table:

![]()

Example:

If the cutting speed recommended in the catalog is 200 m/min and you want a tool life of 45 minutes, the multiplication factor is 0.75. You must therefore use a cutting speed of 150 m/min. For a life of 1 hour use a cutting speed of 140 m/min.

This you would do after selecting the insert grade, chip breaker geometry and cutting parameters as explained in this document and this earlier post in CNCetc.

This table is from a Sandvik turning tools catalog of 1995. I haven’t seen any such factors anywhere else. I’m assuming that these factors are still valid, and I’m assuming that they apply to all operations. Also, somehow no cutting tool catalog mentions the tool life that the recommended parameters are for. I’m assuming that they are for a life of 15 minutes.

Text course: CADEM NCyclopedia multimedia CNC training software.

Etc.

Kolhapur – a sweet city

I was in Kolhapur recently, and saw a lot of jaggery (also common in South America, and called Panela in Spanish). Kolhapur is the jaggery capital of India, and Mahashtra state, where Kolhapur is located, is the biggest producer and consumer of jaggery. Jaggery is made by boiling sugar cane juice till the water evaporates, and then pouring the semi-solid sludge into moulds of various shapes – typically buckets of 1 kg. or 10 kg., or cubes. Pure jaggery is dark brown. For those who think (wrongly) that this is dirty and impure and prefer the ‘pure’ pale yellow jaggery, Calcium Hydroxide is added to lighten the colour.

Jaggery is typically made by the farmers themselves, in a small shed. There’s a small machine to crush the cane, and the juice goes directly into a large pan that is heated from below – the fuel is the dried sugarcane husk itself. It is constantly stirred with a large ladle. In a jaggery factory in Karnataka (it’s called an ‘Aale mane’ in Kannada) I once tried my hand at stirring the semi-solid juice, and boy, it’s really hard work – because of the high viscosity and the large ladle.

Other than the possible Calcium Hydroxide that is non-toxic, jaggery has no other chemicals. White crystal sugar, on the other hand, has a dozen chemicals: lustre enhancer and colourants to improve the aesthetics, and a bunch of chemicals used to speed up the manufacture, reduce losses and improve aesthetics – anti-foaming agent, viscosity reducer, scale inhibitor, floating agent, bacteria inhibitor, colourants.

In my home we switched to using jaggery some years ago for everything – for making sweets, in tea, coffee – and even eat palm jaggery as dessert (made from the juice of palm trees, has a faint taste of coffee).