Machine monitoring for improving production and productivity

This is what typically happens on a manufacturing shop floor:

The scheduling guys make a production schedule for a particular product based on sales, and pass it on to the shop floor guys. They then fold their hands, sit back and relax, thinking that stuff is being made according to the schedule. The story on the shop floor is however different. The machine on which the part is to be made has a breakdown, and the part is not actually being made according to schedule. This is not known till the next morning, when various departments have a meeting. You can change ‘breakdown’ to ‘operator absent’ or ‘no raw material’ or ‘accident’, and the story remains the same. This story can be changed with a machine monitoring system.

This is happening because on the shop floor you may have computers, but these are not talking directly to the machines. People collect data, then enter this data in the computers. This is not done in real time (‘real time’ = the actual time at which an event occurs). The updating of data may be done once a day or once a shift. It may also be manipulated, falsified (and often is). In a manufacturing company, the shop floor is the heart of the company, the place where money is actually made. This HAS to be monitored in real time, so that the rest of the activities can use accurate and timely data.

How do you monitor in real time?

You monitor in real time by making your computers talk directly to the machines, instead of to the people running the machines. People cannot continuously collect data and feed it into into computers 24/7, but machines can, in an Industry 4.0 system. You cannot connect a computers and software directly to most machines (unless the machine itself is computer controlled). This is where a sensor comes in.

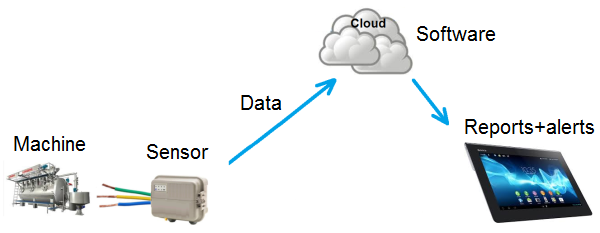

A sensor in Industry 4.0 is a piece of electronic hardware that has inbuilt, or ‘embedded’ software. The sensor senses what the machine is up to at any given instant – what is the production quantity, is the machine running or idle, etc. – and transmits this data through the Internet (this is called IIOT, or Industrial Internet of Things), to a remote computer on the Cloud. Software on this computer analyzes the data and displays reports or generates alerts in case it finds some big problems. So a monitoring system based on Industry 4.0 design principles has the basic Industry 4.0 components shown in this picture.

What can be monitored in a manufacturing shop floor ?

Machines in ANY manufacturing company can be monitored, and Industry 4.0 examples can be found in industries like food, pharmaceuticals, metal parts, plastic parts, textiles, garments, paper, etc. The machine monitoring system tracks the production quantity, machine uptime, machine downtime, reasons for downtimes, and part quality. It reports the production quantity, quality, uptime, downtime, OEE and maintenance parameters. It provides data for preventive maintenance and predictive maintenance. It alerts (through SMS or email) when there’s a production shortfall, too high downtime, too high rejections, breakdown, etc. The reports can be seen on any PC, tablet or mobile phone. The alerts can be seen on a mobile phone or PC.

Etc

Rangoli on my route

On my cycling route to my office every morning is this little street with beautiful rangoli in front of most of the houses. The street in front of each home is nicely washed before the rangoli is drawn. I presume that the few cars that go through the road are careful to not rub them off.

Rangoli is an art form that’s made on the floor in front of homes, or in living rooms. It is usually made of rice flour (hence the white colour), poured in a controlled manner with the fingers. It’s a pleasure to watch a huge beautiful design taking shape where there was just a plain floor before, little by little. The designs can be geometric shapes, birds or flowers. Rangoli is also made with coloured sand, turmeric, brick powder, or with flower petals in festivals like Onam in Kerala. Rangoli is what it’s called in Kannada. It’s called Kolam in Tamil and Malayalam, Muggu in Telugu, Alpana in Bengali, and has other names in various other languages.

Here’s a Pookkalam (that’s what the flower petals variant is called in Malayalam) that we made in our office last year for Onam.