CNC – Eliminate trial part rejection and increase profits

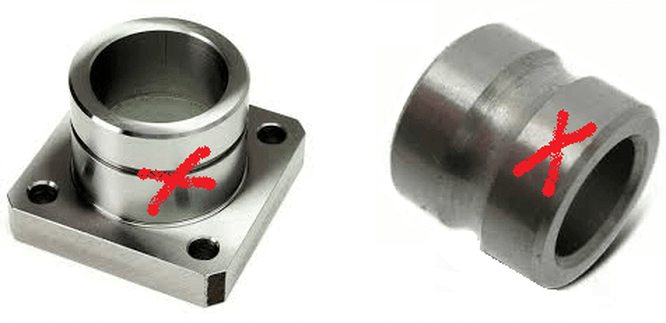

This is one of those “Oh, this is how we’ve always done things here” areas of a shop floor system. When we machine a batch of parts with a new CNC program, we always assume that a couple of parts are going to get rejected while trying out the program, because of program mistakes. This is a reduction in profit by 2 to 5 %. Can anyone really afford this ?

The rejection happens because the program is typically manually writen on a sheet of paper, then entered on the machine and checked through dry run. This only filters out very obvious and glaring errors. Part damage happens in the trial on the first couple of parts, due to dimension errors and not-so-obvious program errors like improper arc radius, programming CW arc instead of CCW arc (writing G02 instead of G03), tool gouge, etc.

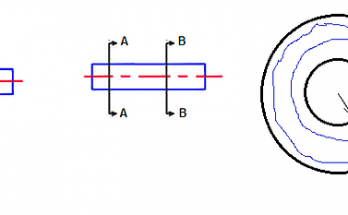

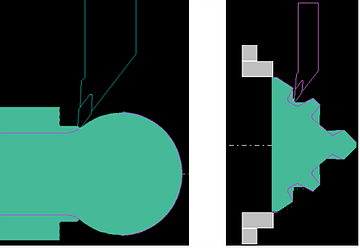

Tool path simulation

The solution is to test the program through graphical simulation in a software on a computer, instead of on the machine. The simulation shows the exact tool holder shape and insert shapes, part and raw material shapes, and part dimensions that you are going to get. Just check the program thoroughly on the computer graphically, eliminate all problems, then run it on the machine. Collisions and part rejections are completely eliminated.

Action point

1. Get an automatic programming software like Cadem CAPSturn CNC lathe programming software and CAPSmill CNC milling programming software. They do the programming for you, and enable you to check the tool path graphically. Cost approx. 1 Lakh (US $ 1600).

OR

2. If you prefer to do manual programming in CNC G and M codes, get CNC program simulation software like Cadem seeNC Turn and seeNC Mill. They enable you to graphically simulate a program written for Fanuc, Siemens, Haas or Mitsubishi. Cost approx. Rs. 25,000 (US $ 350).

Etc.

A liquor shop with a difference

I saw this liquor shop by the highway driving from Ludhiana to Delhi recently. Stopped for a breakfast of parathas at a dhaba, and right beside it was this shop. It’s an old cage for circus animals converted into a shop.

I thought it was a neat idea. Zero constuction cost – probably bought as scrap metal from a circus that went out of business. It’s mobile, so if business is dull at some place you move somewhere else. The show window is visible 24/7, since the shop and the show window are the same. You’ll notice that the name board is taller than the shop itself, and the bunch of hoardings is meant to hit passing motorists on the head with the message.

In the 1990s, wild animals like lions, bears, monkeys and panthers were banned from circuses in India. In 2013 elephants were banned too. Domestic animals like horses, dogs and camels are still used. Here’s a picture of what the cage would have looked like when in use.