Industry 4.0 technologies and key components – what are they ?

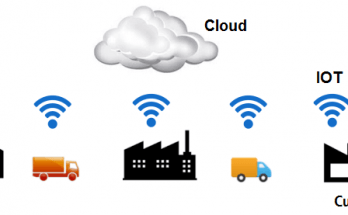

Industry 4.0 has these three key components: Cyber physical system, IOT and Cloud computing. Each of these components uses specific Industry 4.0 technologies.

Cyber-physical system (CPS) in Industry 4.0: This is a mechanism controlled or monitored by computer-based algorithms, tightly integrated with the internet and its users. Basically, a machine that is controlled or monitored by a computer that is directly connected to the internet. Cyber means ‘involving, using or relating to computers’ (as in cyber-space or cybercafe). The machine can be anything at all – for metal forming, metal cutting, making textiles, pharma, food processing, etc. The computer is usually an embedded system, a small computer with the dedicated function of controlling or monitoring the particular machine. This is called the Sensor in Industry 4.0. It has inputs and outputs that are connected to the electronics on the machine, and the ability to talk (i.e., send and receive data) to the internet.

IOT in Industry 4.0: IOT is the Internet of Things. It is the same old internet that people have been using for some decades now, but are now also used by things, since a few years. The internet of course is a global computer network providing a variety of information and communication facilities. The things in IOT could be robots, manufacturing machines, mobile phones, medical equipment, cars, CCTV cameras, etc. IIOT (note the extra I) is Industrial Internet of Things, the internet used used by machines in industry.

Cloud computing in Industry 4.0: The cloud is a network of remote servers hosted on the internet to store, manage, and process data, rather than a local server or a personal computer. A server is more powerful and reliable version of a normal PC, with a more powerful CPU, larger storage space, and reliability required to run 24/7. More info. The sensor gets data from the machine in the cyber-physical system, sends this data to a cloud server over the internet. Software on the server takes this data, analyzes it, and does one or more of these:

– Displays something to humans

– Does something itself (e..g, automatically reorder raw material based on consumption)

– Tells the machine to do something (e.g., stop, speed up or slow down)

– Tells some other machine to do something

That’s it. Simple. For any Industry 4.0 application that you want to implement, design principles are based on the use of these basic Industry 4.0 technologies.

Etc

My 100 km bike ride, and my (temporarily) destroyed self-esteem

I recently cycled 100 km. between a couple of towns in North Karnataka. Beautiful terrain, lovely weather, sparse traffic, plentiful Oxygen. The only problem was that I stopped appreciating all these after about 50 km. This is what happened: I started off around 8 AM thinking I’d have breakfast at some interesting place on the way. After 20 km I still wasn’t feeling hungry, so I just had a couple of bananas.

The road was great, but went up and down a whole lot of hills. Every up-slope of course was balanced out by a down-slope, and theoretically, the energy that I spent on the ups was being balanced out when I coasted on the downs. Turns out that this is not how your muscles work. My leg muscles were aching like crazy by the time I was done with an up slope, and weren’t happy with the rest they got on the way down. On the next up, instead of saying “All right, we can do this, we’re all fresh from the rest”, they said “What, again ? What does this idiot think we are, some machines ?”. After 40 km the going got really tough, and my legs were really complaining. On some steep slopes I actually got off and walked, wondering if I could even finish the 100 km or would have to hop on to a passing truck with the bike.

The road was great, but went up and down a whole lot of hills. Every up-slope of course was balanced out by a down-slope, and theoretically, the energy that I spent on the ups was being balanced out when I coasted on the downs. Turns out that this is not how your muscles work. My leg muscles were aching like crazy by the time I was done with an up slope, and weren’t happy with the rest they got on the way down. On the next up, instead of saying “All right, we can do this, we’re all fresh from the rest”, they said “What, again ? What does this idiot think we are, some machines ?”. After 40 km the going got really tough, and my legs were really complaining. On some steep slopes I actually got off and walked, wondering if I could even finish the 100 km or would have to hop on to a passing truck with the bike.

I finally had lunch in a town at the 60 km mark, and got going again after a short rest. The road thankfully flattened out after this, and the hills and forests around me were replaced by paddy fields. The legs however still remembered the morning’s punishment and were only half happy. Hitting my destination at 4 PM was the ultimate joy, but I was quite disgusted with myself by then, thinking that people ride 3500 km in the Tour de France race, and here I was struggling to do 100 km.

After I got back home to Bangalore, I took a few deep breaths of Carbon Monoxide and got on to the www to see what I’d done wrong. I saw a whole lot of articles titled ‘How to prepare for your first 100 km ride’, and thought “What, you actually have to prepare for your first 100 km ride?”. It turns out that people actually train a few weeks before doing this, they eat a substantial breakfast before setting off, and carry stuff like energy bars to munch on the way. So I’d done EVERYTHING wrong. After this my self-esteem went up a bit, and I concluded that the problem was with my brain, not my legs. Eating nothng in the morning, 2 bananas after 20 km and lunch after 60 km – what the hell was I thinking ?

I also got another horrifying thought: What if my problem was the air that I was breathing ? What if my body, after living for so long in a city, has gotten unused to breathing Oxygen and can only live on a cocktail of Carbon Monoxide + SO2 + NOx ? Like the Nitrogen fixing bacteria in soil, that breathe Nitrogen. Maybe on my next ride I’ll try taking along a canister of pressurized city air cocktail.