Why you cannot cut steel with PCD tools (Diamond tools)

Diamond is great cutting tool material, but diamond tools (actually technically PCD tools) cannot cut ferrous metals like Steel or Cast Iron. Here’s the reason.

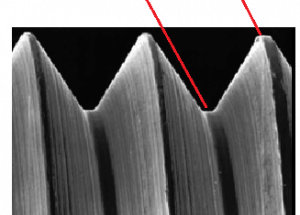

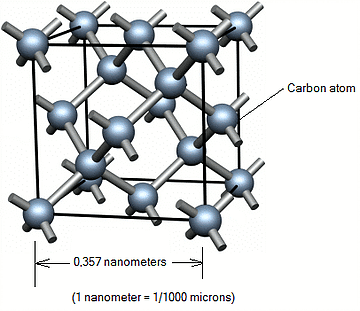

Diamond is essentially pure carbon, with atoms arranged in a cubic crystal arrangement that makes it very strong. A piece of diamond is a single large crystal. If you cut steel with diamond, at higher temperatures (more than 700 deg. C), the Carbon atoms react with Iron to form Iron Carbide (Fe3C). The carbon atoms basically divorce their old Carbon partners in the crystal structure, get hitched to some new Iron partners, and the crystal structure collapses, making the tool useless.

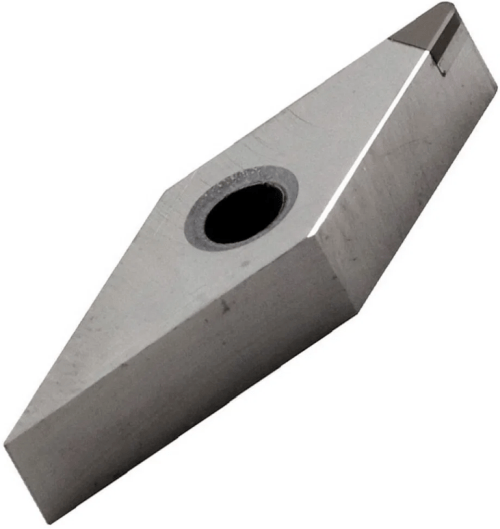

What we call diamond tools are actually PCD tools, PCD standing for Poly Crystalline Diamond. PCD is produced synthetically by sintering together many (hence the Poly) diamond particles, usually 2 to 30 microns each, with a metal binder (usually Cobalt) at high temperature and high pressure. In the resultant mass, diamond particles are about 95% and the rest is Cobalt.

Each carbon atom is covalently bonded to four other carbon atoms. A lot of energy is needed to separate the atoms in diamond. This is because covalent bonds are strong, and diamond contains many covalent bonds. This also makes diamond’s melting point and boiling point very high. There are no free electrons or ions in diamond, so it does not conduct electricity.

This extra bit of knowledge is for those of you with kids in high school, who had to dig up some of your long-buried chemistry knowledge so you can clear their doubts. I went through this phase a few years ago, and hence still remember the covalent bond and other chemistry stuff. Thankfully my kid then moved to college doing law, of which I knew nothing and hence could not help her in any way.

With the sad exception of ferrous metals (sad because most of our metal cutting is on steel and cast iron) and Titanium, PCD does not bond with any work piece materials. Because of this the built-up edge too is minimal. So the high hardness, high temperature resistance and no built-up edge make PCD tools or diamond tools great for cutting.

Transform production and profits dramatically, in just a few months.

With a CNC machine monitoring system.

Etc

Lunch in Sandur, Karnataka

Lunch in the hostel mess in my old school. A group of us old students landed up unannounced, and the cook made something in a hurry. Seriously simple stuff, North Karnataka style. Dry Jowar roti and a palya (sabzi). The yucky looking thing that looks like a dead animal is actually a whole brinjal (egg plant) cooked in a style peculiar to North Karnakata, and is very tasty.

Sandur is in the heart of the mining area in Bellary, in North Karnakata. I did a few years of schooling there (the rest being in Chattisgarh, Jharkhand, AP, TN and Orissa). When you read about Karnataka’s mining scandals in newspapers, this is the place they are talking about.

Sandur used to be a very green area, with thick forests, streams and lots of wildlife. It became a brown wasteland because of illegal iron ore mining for a couple of decades. The greenery is now partially back, but can sadly never be fully back because of the irreversible destruction.